XINXIN accessories are designed with the principles of “high integration, intelligent linkage, and modular expansion,” enabling seamless integration with film blowing, printing, and bag-making main lines to achieve an integrated production process from film processing to bag packaging and boxing.

Furthermore, all accessories support customization: functional modules such as bag sorting, box loading, strapping, edge sealing, and edge insertion can be configured according to customer requirements, flexibly adapting to different production line layouts and product characteristics. Whether for food packaging, medical supplies, garment bags, e-commerce logistics bags, or household goods packaging, Xinxin's auxiliary equipment delivers systematic solutions offering higher efficiency, superior quality, and lower costs.

Yes. We support global export of all accessories and spare parts. With extensive experience shipping to over 80 countries, we ensure efficient logistics to get the required parts to your production line promptly.

Replacement intervals depend on usage, but items like Teflon/Silicon belts or punching blades are typical consumables. We provide maintenance guidelines and these genuine parts are readily available for quick replacement to minimize downtime.

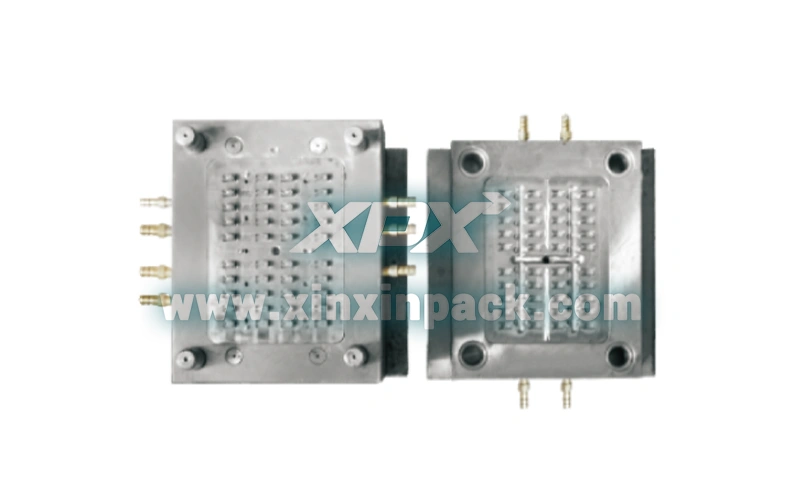

We use high-grade materials: high-temperature resistant Teflon for sealing belts, durable engineering plastics for reels, and precision-hardened steel for punching tools to ensure durability and consistent performance.

Absolutely. Our accessories, from punching units to film width controllers, are precision-engineered to match our machinery models, guaranteeing seamless integration and maintaining original equipment specifications.

Yes. Using our genuine accessories like Teflon belts and silicone belts ensures perfect fit, optimal performance, and long-term reliability for your zipper bag production line, protecting your investment.

After-sales issues

Pre sales issues

Customized issues

Environmentally friendly materials

Integrated production lines

Maximising your return on investment