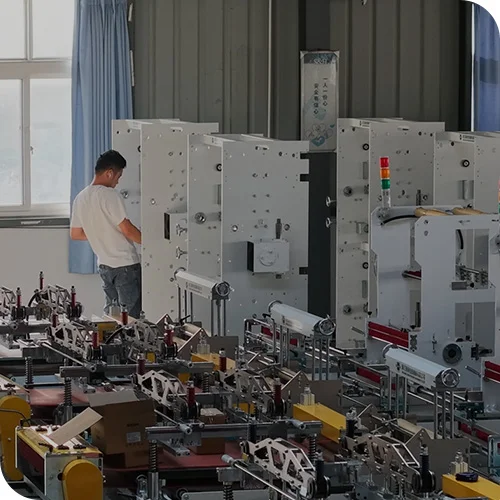

The XinXin printing press series is specifically designed for blown film production lines, and can be directly connected to zip-lock bag blown film machines or flatbed blown film machines to achieve integrated blown film, printing, and bag making operations. The equipment supports 2-6 color flexographic or gravure printing, and employs high-precision color mark photocells and a constant tension control system to ensure stable pattern registration and vibrant colors. Suitable for PP, PE, and other plastic film materials, it is widely used in flexible packaging fields such as food packaging bags, garment bags, diaper bags, and express delivery bags, providing customers with efficient and labor-saving intelligent printing solutions.

Plastic film, paper, and non-woven fabric

Multi-color continuous printing

BOPP, PET, CPP, and nylon

Fast printing speeds and stable colors

Designed for high-speed, continuous production

Automatic roll changing, electronic shaft synchronization control, and constant tension closed-loop control.

Yes. We offer custom printing solutions, including color configuration and drying system adjustments, to meet specific customer packaging and production requirements.

It features a PLC touchscreen control system for precise registration, automatic tension control, and easy operation, ensuring stable, high-quality printing.

They are suitable for PP, PE, and other plastic films, ensuring excellent ink adhesion and print clarity for flexible packaging.

We offer printing machines supporting 2 to 6 colors, providing vibrant, accurate printing for brand logos and complex patterns on various films.

Yes. Our flexo and gravure printers are designed for inline connection with film blowing or bag-making lines, enabling efficient blown-film-printing-bag-making integration.

After-sales issues

Pre sales issues

Customized issues

Environmentally friendly materials

Integrated production lines

Maximising your return on investment