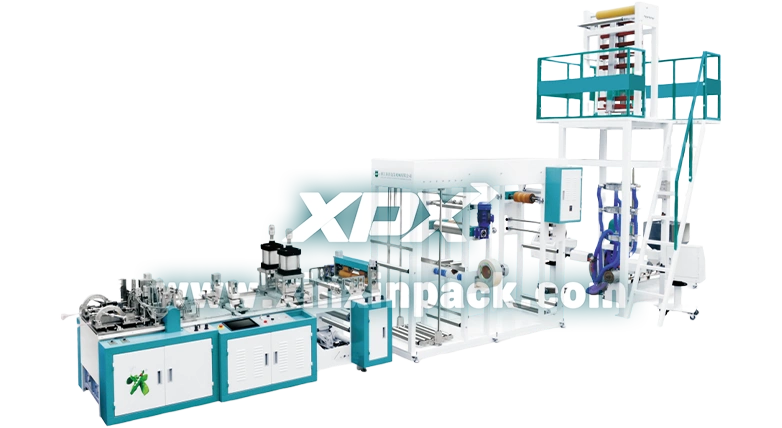

This fully automated equipment is specifically designed for the production of plastic sausage casings, integrating extrusion molding, cooling and sizing, and traction winding.

The equipment operates stably, produces uniform film, and generates precise casing dimensions. Different diameters and thicknesses can be customized to meet customer needs, and it is widely used in the packaging of sausages, ham sausages, and other meat products.

Industry end-users: Meat processing plants, sausage manufacturers, cooked food production workshops, and frozen meat processing enterprises.

We provide integrated production line solutions for sausages, hams, and cooked food products, from raw material casing manufacturing, filling, connecting and knotting, drying to packaging.

Environmentally friendly materials

Integrated production lines

Maximising your return on investment