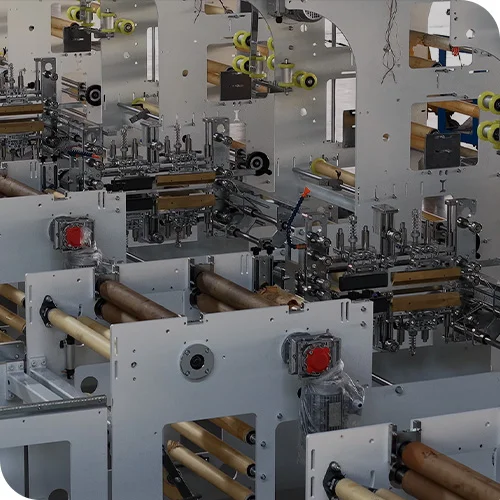

Our blown film extrusion machine series encompasses various models, including ziplock bag blown film extrusion machines, water-cooled ziplock bag blown film extrusion machines, dual-head blown film extrusion machines, multi-layer co-extrusion blown film extrusion machines, and high-speed flat film blown film extrusion machines, comprehensively meeting diverse needs from standard production to high-end customization.

This entire series of equipment is widely applicable to raw materials such as LDPE, LLDPE, and PP. Utilizing a high-efficiency screw extrusion system and servo control technology, it achieves uniform film thickness, high transparency, and excellent sealing performance. Some models are equipped with water-cooled setting, dual-head co-extrusion, multi-layer co-extrusion, and high-speed winding systems, increasing capacity by 30%–50%, achieving smoother winding, and reducing energy consumption by 20%.

The equipment features a robust structure and simple operation. Film widths range from 480–600 mm, with a maximum output of 70 kg per hour. The blown films can be directly used in various industries such as ziplock self-sealing bags, food packaging, clothing packaging, and daily necessities packaging, providing users with a high-efficiency and highly stable production solution.

Material: LDPE

Output, blown film speed, configuration, stability, product aesthetics, ease of operation, service life, various materials, zipper buckle type, zipper color, and zipper style.

Material: PP, LDPE

Water-cooled shaping, automatic zipper lamination, tension control, transparent film forming, stable film output, and wrinkle-free production.

Material: LDPE

LDPE material blown film, zipper structure integration, automatic film roll output, stable film thickness, and quick changeover.

Material: LDPE

Dual-head synchronous extrusion, simultaneous cooling of two rolls of film, integrated zipper structure, and doubled production capacity design.

Material: LDPE

Multi-layer material co-extrusion, improved barrier performance, zipper and film structure integration, energy-saving design, and recyclable material compatibility.

Materials: HDPE, LDPE, LLDPE

High-speed blown film, high output, stable film thickness, automatic film winding, easy operation, and compatibility with multiple materials.

Materials: HDPE, LDPE, LLDPE

Double-layer co-extrusion system, flexible material combination, improved film performance, user-friendly interface, energy saving and consumption reduction.

Yes. We provide custom multi-layer co-extrusion zipper film blowing machines for producing high-barrier, functional films tailored to specific packaging needs.

Core advantages are high output and stability. It uses premium components (motors, screws) and precision dies to ensure excellent film properties and strong zipper profiles.

Yes. Our machine can be adjusted to process biodegradable materials like PLA/PBAT, enabling the production of eco-friendly zipper bag film.

Depending on the model, stable production speeds reach 18-20 meters/minute. Servo control and optimized cooling ensure high, consistent output of quality film.

It specializes in producing zipper-seal films from materials like LDPE and PP, creating high-transparency, uniform-thickness film rolls as premium substrates for subsequent bag-making.

After-sales issues

Pre sales issues

Customized issues

Environmentally friendly materials

Integrated production lines

Maximising your return on investment