Customized production is supported; bag type (insertion, embossing), color, printing content, and packaging method can be adjusted according to customer needs.

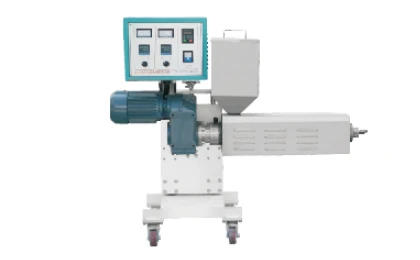

This model is primarily designed for the integration of blown film production and zipper structure for LDPE material films. The equipment is equipped with synchronous feeding, a touch interface, and an automatic alarm control system, enabling efficient coordinated production of zipper film and bag material, suitable for manufacturing various sizes of zipper bags.

End-user applications: Food, pharmaceuticals, apparel, electronics

LDPE material blown film, zipper structure integration, automatic film roll output, stable film thickness, and quick changeover.

| Model | ZIP-55 | ZIP-65 |

| Material | LDPE | LDPE |

| Screw Diameter | Φ55mm | Φ65 mm |

| Screw Draw Ratio | L/D 32:1 | L/D 32:1 |

| Max Output | 30kg | 40kg |

| Film Width | 500mm | 600mm |

| Dimension | 6500×2300×5300mm | 6500×2500×5000mm |

| Weight | 2.8T | 3.2T |

Environmentally friendly materials

Integrated production lines

Maximising your return on investment