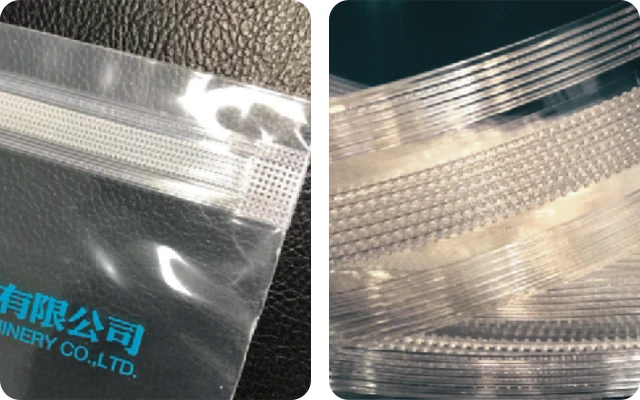

This equipment is used to produce hook-and-loop zipper strips, also known as "hook-and-loop zippers." It utilizes plastic extrusion molding technology to form the hook and loop sides in a single process, resulting in strong adhesion and smooth opening and closing. Suitable for high-sealing, reusable packaging bags, such as food bags, freezer bags, and storage bags. The production process is stable, producing zipper strips with a neat appearance and smooth feel. Different colors, shapes, and widths of zipper strips can be customized according to customer needs.

The multi-screw synchronous extrusion structure is suitable for high-precision molding of hook and loop zippers; the zipper width and tooth structure can be customized; multi-color co-extrusion is supported; the water-cooled shaping channel design ensures that the hook and loop structure is flat and has high bonding strength.

| Model | ZIP-50 |

| Speed | 30m/min |

| Extruder Width | 10-50mm |

| Material | PE, PP |

| Dimension | 8500×1200×1800mm |

| Power | 15KW |

| Weight | 2.2T |

Environmentally friendly materials

Integrated production lines

Maximising your return on investment