Customized production is supported; bag type (insertion, embossing), color, printing content, and packaging method can be adjusted according to customer needs.

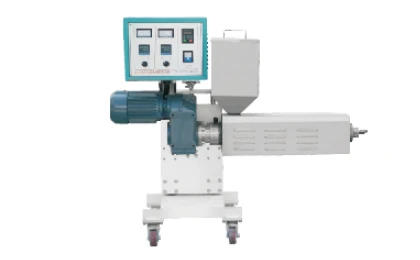

This equipment is specifically designed for producing films with zipper structures, enabling simultaneous film extrusion and zipper profile forming. Through key technologies such as screw extrusion, air ring cooling, and film belt tension control, it ensures a smooth film surface and a secure zipper seal. Its high-speed production capacity makes it an ideal machine for manufacturing zippered self-sealing bags.

End-user applications: Food, pharmaceuticals, apparel, electronics, auto parts, jewelry

Material: LDPE

Customized production is supported; bag type (insertion, embossing), color, printing content, and packaging method can be adjusted according to customer needs.

Output, blown film speed, configuration, stability, product aesthetics, ease of operation, service life, various materials, zipper buckle type, zipper color, and zipper style.

| Model | ZIP-55H | ZIP-65H |

| Material | LDPE | LDPE |

| Screw Diameter | Φ55 mm | Φ65 mm |

| Screw Draw Ratio | L/D 32:1 | L/D 32:1 |

| Max Output | 40kg | 50kg |

| Film Width | 500mm | 600mm |

| Dimension | 6500×2500×5000mm | 6500×2500×5000mm |

| Weight | 3.5T | 4.5T |

Environmentally friendly materials

Integrated production lines

Maximising your return on investment