Support customization according to needs, and can be equipped with multiple functional accessories to achieve multi-purpose use of one machine, meeting the needs of different bag types.

Used for producing various resealable zipper bags, automatically completing sealing, bag cutting, and other processes. It operates quickly and is easy to use, suitable for food bags, garment bags, storage bags, and other packaging applications.

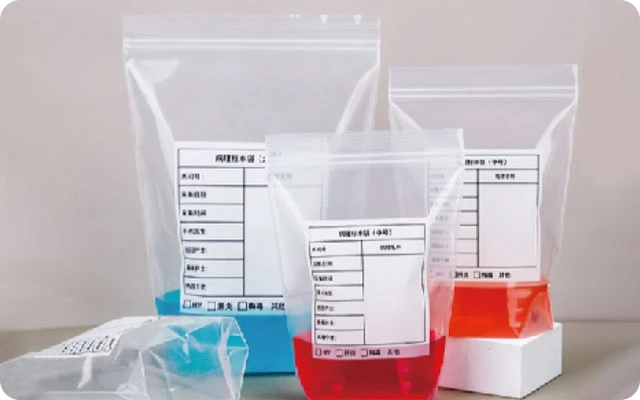

Industry Applications: Food packaging, daily necessities packaging, electronic component packaging, medical supplies packaging, fruit and vegetable packaging, clothing lining bags, home storage, and small hardware item packaging.

Materials: LDPE/PP/PVC/Non-woven fabric/OPP/Composite film/LLDPE

Bag Types: Grocery packaging bags, daily necessities packaging bags, small retail zipper bags.

High-efficiency bag making, automatic deviation correction and tension control, PLC control interface, adaptability to multiple materials.

High bag making speed, wide range of bag width/length adaptability, diverse film/bag materials, and strong equipment compatibility.

| Model | ZIP-500H | ZIP-600H |

| Speed | 50-230pcs/min | 50-230pcs/min |

| Bag Width | 480mm | 580mm |

| Material | LDPE | LDPE |

| Dimension | 4200×1300×1700mm | 4200×1500×1700mm |

| Voltage | AC220V 50Hz | AC220V 50Hz |

| Power | 5KW | 6KW |

| Weight | 1.5T | 1.7T |

Environmentally friendly materials

Integrated production lines

Maximising your return on investment